In the bustling heart of every successful restaurant or culinary establishment lies the industrial kitchen—a realm where precision, efficiency, and creativity collide to create mouthwatering masterpieces. Whether you are a seasoned chef or an aspiring restaurateur, the importance of having the right tools and equipment cannot be overstated. In this listicle, we will explore 24 essential elements that every industrial kitchen must have to ensure a smooth operation, boost productivity, and enhance the overall culinary experience. From high-capacity appliances to essential utensils, each item plays a crucial role in enabling chefs to unleash their potential. Join us as we delve into this comprehensive guide where you will discover not only what you need but also the unique features and benefits of each essential element that can transform your kitchen into a well-oiled machine. Ready to elevate your cooking space? Let’s get started!

Ample workspace is vital for every efficient industrial kitchen setup and flowing workflow

In the bustling environment of an industrial kitchen, having ample workspace is not just a luxury; it’s a necessity that directly impacts the efficiency and productivity of the entire operation. Employees need sufficient room to maneuver, especially when handling large quantities of food and various kitchen equipment. A well-organized layout with designated areas for preparation, cooking, and plating can prevent cross-contamination and optimize movement, allowing chefs to focus on delivering exceptional dishes without the distraction of cluttered countertops. Additionally, an expansive workspace facilitates teamwork, where multiple staff members can collaborate seamlessly without hindering each other’s tasks.

To maximize efficiency in your kitchen setup, consider integrating the following elements into your design:

- Modular Stations: Create versatile workstations that can be easily reconfigured according to daily needs.

- Height-Adjustable Counters: Accommodate staff of varying heights, thereby improving ergonomics and reducing fatigue.

- Dedicated Waste Areas: Provide clearly marked, easily accessible bins for waste and recycling to maintain cleanliness.

- Incorporated Storage Solutions: Use shelves, cabinets, and racks that blend seamlessly into the workspace to keep essentials within reach.

By ensuring a layout that promotes an open and organized environment, industrial kitchens can not only enhance workflow but also elevate the overall culinary experience. Proper spacing allows chefs to execute their craft efficiently while minimizing the potential for accidents and injuries. For further insights on optimizing kitchen layouts, consider exploring culinaryschoolguide.com, which offers valuable resources on best practices for kitchen design.

Commercial-grade ovens ensure consistent cooking results in a busy industrial kitchen environment

In the whirlwind of an industrial kitchen, where time is of the essence and menu items are flying out of the oven, having a commercial-grade oven is non-negotiable. These powerful units are designed to handle the relentless pace and ensure that every dish comes out perfectly cooked, no matter how hectic service gets. With features like consistent temperature control and even heat distribution, they provide a reliable backbone for culinary creativity. The precision of these ovens means chefs can count on repeatable results, whether they’re baking dozens of pizzas or roast meats for large gatherings. The moment you turn that dial, you’re setting the stage for success.

Commercial-grade ovens boast a range of *features* that cater specifically to the demands of a busy kitchen environment:

- Multi-function Capability: These ovens often combine various cooking methods, allowing chefs to bake, roast, and broil all in one unit.

- High-Volume Output: They are built to handle large quantities of food, making them ideal for catering and restaurants with high service demands.

- Durability: Constructed with robust materials, they withstand the rigors of daily use, ensuring longevity and dependability.

- Energy Efficiency: Many commercial ovens are designed to be energy-efficient, saving costs while maintaining high performance.

- Advanced Controls: User-friendly interfaces allow precise adjustments, helping chefs attain the desired cooking results effortlessly.

To visualize how essential these ovens are in daily operations, consider the following comparison:

| Oven Type | Cooking Capacity | Typical Use |

|---|---|---|

| Commercial Convection Oven | 6-10 sheet pans | Baking, Roasting |

| Combi Oven | 5-7 racks | Steaming, Baking |

| Pizza Oven | 2-4 pizzas at a time | High-temperature baking |

Choosing a commercial-grade oven can make all the difference for chefs looking to streamline their processes and elevate their culinary output. For more insights into commercial kitchen equipment, check out Restaurant Supply.

A sturdy refrigerator maintains food safety standards in an industrial kitchen setting

A robust refrigeration system is the backbone of any industrial kitchen, ensuring that ingredients remain fresh and safe for consumption. In a bustling culinary environment, maintaining appropriate temperatures is crucial to prevent foodborne illnesses. A high-quality refrigerator must possess advanced cooling technology, durable construction, and an energy-efficient design to withstand the rigors of daily use. These features not only prolong the lifespan of the unit but also enhance energy savings, lowering operational costs.

When choosing a refrigerator for an industrial kitchen, consider the following essential features:

- Temperature Control: Easy-to-use digital controls that allow precise temperature adjustments.

- Adjustable Shelving: Versatile shelving that provides flexibility for storing various food items.

- Accessibility: Wide doors and ergonomic designs for quick access to ingredients while minimizing temperature fluctuations.

- Monitoring Systems: Integrated alarms that notify kitchen staff of temperature anomalies to maintain compliance with health standards.

- Sanitation Features: Smooth, seamless surfaces that are easy to clean and resistant to bacterial growth.

For more detailed information on food safety standards, visit fsis.usda.gov.

| Feature | Description |

|---|---|

| Economical Operation | Designed for energy efficiency to reduce utility costs. |

| Durability | Built with heavy-duty materials to resist wear and tear. |

| Storage Capacity | Ample space for bulk storage of perishable goods. |

Heavy-duty countertops accommodate the rigorous demands of an industrial kitchen

In an industrial kitchen, the demands for surface durability and hygiene are paramount. Heavy-duty countertops provide the perfect solution, leveraging materials such as stainless steel, quartz, and solid surface composites that are designed to withstand constant use, heavy weights, and high temperatures. These robust surfaces not only resist scratches and stains but also ensure a clean, sanitary workspace, crucial in food preparation environments. The choice of material can significantly affect functionality, so many kitchens opt for surfaces that balance resilience with style.

Moreover, the design of these countertops often incorporates practical elements that enhance efficiency and workflow. Features such as integrated sinks, built-in cutting boards, and drainage grooves can streamline operations. Additionally, countertops can include heat-resistant edges for safe placement of hot pans and dishes. Below is a comparison of popular heavy-duty countertop materials used in industrial kitchens:

| Material | Durability | Maintenance | Cost |

|---|---|---|---|

| Stainless Steel | Highly Durable | Easy to Clean | High |

| Quartz | Very Durable | Low Maintenance | Moderate |

| Solid Surface | Durable | Simple Cleaning | Moderate to High |

Investing in top-quality countertops not only enhances the efficiency of the workspace but also extends the life of kitchen fixtures. Proper selection and installation can provide a long-term solution that meets the rigorous demands of a bustling industrial kitchen. For further insight into choosing the right product for your needs, visit The Spruce Eats.

State-of-the-art dishwashers streamline cleaning processes in an industrial kitchen

In the bustling atmosphere of an industrial kitchen, efficiency is paramount, and state-of-the-art dishwashers stand at the forefront of this transformation. These modern marvels not only boast sleek designs but also feature advanced technology that optimizes the cleaning process. Equipped with high-performance jets and powerful water circulation, they ensure every plate, pot, and utensil comes out spotless, minimizing manual labor and maximizing hygiene standards. Automated settings adjust based on load size and soil levels, dramatically reducing water and energy consumption, making them a sustainable choice for any kitchen.

Moreover, many of these innovative dishwashers come integrated with smart technology, allowing kitchen staff to monitor performance remotely or schedule cleaning cycles during off-peak hours. This flexibility aids in maintaining a streamlined workflow, ensuring that clean dishes are always at hand for service. Consider features like self-diagnostic tools and real-time alerts for maintenance needs, which help preempt downtime and extend the lifespan of these essential appliances. These dishwashers can transform the back-of-house operations, allowing chefs and staff to focus on food preparation rather than cleaning logistics. For further insights on the latest in commercial kitchen equipment, visit restaurantsupply.com.

Quality cookware is essential for producing diverse dishes in an industrial kitchen

Quality cookware is the backbone of any industrial kitchen, allowing chefs to explore and execute a wide array of dishes with precision and ease. When equipped with the right pots, pans, and utensils, culinary professionals can ensure that flavors are enhanced and textures are perfected. High-quality cookware can withstand high heat, distribute it evenly, and resist warping, which is crucial when preparing large quantities of food. Furthermore, using non-reactive materials, such as stainless steel or high-grade cast iron, ensures that the integrity of ingredients is maintained, whether simmering delicate sauces or searing meats.

To achieve culinary creativity and efficiency, it’s essential to have a variety of cookware designed for specific tasks. Stockpots, sauté pans, griddles, and non-stick skillets each serve a unique purpose in the cooking process. A well-rounded collection will empower chefs to whip up everything from rich, hearty stews to delicate, flaky pastries. Here’s a brief overview of essential cookware types that every industrial kitchen should consider:

| Cookware Type | Primary Use |

|---|---|

| Stockpot | For soups, stocks, and boiling pasta |

| Sauté Pan | For browning meat and quick-cooking vegetables |

| Cast Iron Skillet | For frying, baking, and slow-cooking |

| Non-stick Frying Pan | For delicate dishes like eggs and pancakes |

Investing in quality cookware not only enhances the cooking process but also elevates the overall dining experience, allowing chefs to serve beautifully crafted dishes with ease. For those looking to delve deeper into cookware selections, consider visiting reputable culinary resources, like Serious Eats, which offers insights into the best products available in the market.

Industrial kitchen ventilation systems keep air quality safe and comfortable for chefs

Efficient ventilation systems are crucial in an industrial kitchen, as they primarily ensure that the air quality remains safe and comfortable for chefs. A well-designed system effectively removes smoke, grease, odors, and excess heat that can accumulate during busy service hours. This not only enhances the working environment but also reduces the risk of respiratory issues and provides a more enjoyable atmosphere for the culinary team. By maintaining proper airflow, ventilation systems help to regulate humidity levels, which can prevent mold growth and ensure food safety standards are upheld.

Moreover, modern industrial kitchen ventilation systems often come equipped with advanced features that contribute to both functionality and energy efficiency. Here are a few highlights to consider:

- Heat Recovery: Systems that capture heat from exhaust air can repurpose it for preheating incoming air or hot water, significantly lowering energy costs.

- Filtration Technology: High-efficiency filters help trap grease and particulates, extending the life of equipment and improving air quality.

- Smart Controls: Automated systems that adjust airflow based on kitchen activity levels can optimize performance and prevent energy waste.

Investing in a robust ventilation system not only safeguards the health of the kitchen staff but also supports the overall productivity of the culinary operation. Consider exploring more about the importance of kitchen ventilation by visiting hvac.com for in-depth insights and product recommendations.

Versatile mixers speed up food preparation tasks in a professional industrial kitchen

In a bustling industrial kitchen, time efficiency is key, and versatile mixers are indispensable tools that streamline food preparation tasks. These high-powered appliances can handle a variety of tasks, from mixing dough for artisan bread to whipping cream for dessert garnishes. Their ability to seamlessly transition between different types of ingredients makes them essential for busy chefs who need to maximize productivity without compromising on quality. Stand mixers, for instance, come with various attachments that allow them to blend, knead, and even shred, thus reducing the need for multiple appliances and saving precious counter space.

Furthermore, the ease of use and precision offered by modern mixers can significantly enhance food consistency and reduce manual labor. With features like variable speed settings and powerful motors, these mixers can tackle everything from delicate emulsions to heavy batters. Many models are designed with a tilt-head or bowl-lift mechanism, making it easy to access the ingredients without interrupting the mixing process. This versatility ensures that kitchen staff can efficiently prepare large quantities of food while maintaining a high level of craftsmanship. For those interested in exploring a wide variety of mixer options, check out bhg.com for useful insights and recommendations.

Adequate shelving units provide organized storage in an industrial kitchen

In the bustling environment of an industrial kitchen, adequate shelving units serve as the backbone of organized storage. Having the right type of shelving not only maximizes space but also streamlines kitchen operations. The proper placement of shelves allows chefs to quickly access dry goods, utensils, and equipment, enabling smoother workflows. Consider incorporating a mix of open shelves, wall-mounted units, and mobile shelving to provide versatility and ease of access for all kitchen staff. These elements help to create a clean aesthetic while ensuring that everything has a designated place.

When choosing shelving units, it’s crucial to select durable materials that can withstand the rigors of kitchen use. Look for features like rust-resistant finishes and adjustable shelves to accommodate varying item sizes. Some effective shelving solutions include:

- Stainless Steel Shelves: Perfect for heavy-duty usage and easy to clean.

- Wire Racks: Allow for air circulation and visibility while supporting substantial weight.

- Wooden Shelves: Offer a more rustic appearance and are ideal for lighter, decorative items.

Implementing a tiered shelving unit not only enhances vertical storage but also encourages a systematic approach to ingredient categorization. For instance, a simple classification based on ingredient types can help kitchen teams quickly locate what they need, leading to increased efficiency. Consider utilizing labels or color-coded bins for a more streamlined experience. For additional tips on organizing commercial kitchens, check out FoodServiceWarehouse.com.

Reliable food processors enhance efficiency and creativity in an industrial kitchen

In an industrial kitchen where time is of the essence, reliable food processors stand as indispensable allies for chefs. These machines multiply productivity, allowing culinary professionals to prepare larger quantities of food with precision and speed. From chopping vegetables to blending sauces and even kneading dough, food processors streamline various tasks that would traditionally consume significant time and labor. With each slice and puree executed effortlessly, chefs can focus on creativity rather than tedious preparation, resulting in dishes that resonate with quality and flavor.

Moreover, the versatility of modern food processors unlocks innovative culinary possibilities. Equipped with multiple attachments and settings, they can be tailored to perform specific tasks such as shredding, grating, and emulsifying, broadening the scope of ingredients that chefs can incorporate into their menu. This adaptability not only enhances efficiency but also ignites creativity, empowering chefs to experiment with flavors and textures. Investing in a high-quality food processor is not just about saving time; it’s an essential step towards elevating the overall culinary experience in any bustling kitchen. For more insights on optimizing kitchen efficiency, visit woodlandfoods.com.

Commercial fryers deliver high volume frying capabilities for an industrial kitchen

When it comes to frying in an industrial kitchen, commercial fryers are indispensable for their ability to handle high-volume demands with ease. These machines are engineered to accommodate a variety of frying processes, from crispy fries to perfectly golden chicken. The efficiency of these fryers ensures that staff can keep up with the fast-paced environment, making them an essential investment for any high-demand food service operation. Key benefits include:

- Robust design: Built to withstand constant use, they are ideal for busy kitchens.

- High output: Capable of frying large quantities at once, reducing wait times for customers.

- Temperature control: Advanced controls allow for precise frying temperatures, ensuring food safety and quality.

- Versatility: Suitable for a range of fried foods, from appetizers to main dishes.

Beyond performance, commercial fryers also enhance operational efficiency. Many models come with features designed to reduce oil replacement frequency and improve safety standards. They often include filtration systems that prolong oil life, which is not only cost-effective but also improves food quality. Additionally, many units have safety features, including automatic shut-off and cool-touch exteriors, allowing kitchen staff to work with peace of mind. These features make commercial fryers a vital component for businesses aiming to deliver exceptional fried culinary delights consistently. Some leading suppliers include EquipmentFacts, offering a variety of options to suit every kitchen’s needs.

A walk-in freezer allows bulk storage in a well-planned industrial kitchen

In any bustling industrial kitchen, a walk-in freezer serves as a game changer, enabling chefs to manage large quantities of food efficiently and effectively. This specialized cold storage unit not only conserves space but also enhances the kitchen’s productivity by allowing for bulk purchases, seasonal menu adaptations, and streamlined inventory management. Consider the following benefits that a walk-in freezer provides:

- Maximized Storage Capacity: Generous shelving and floor space keep items organized and accessible.

- Enhanced Food Safety: Maintaining optimal temperatures minimizes the risk of spoilage and bacterial growth.

- Cost Efficiency: Buying ingredients in bulk can lead to significant savings while allowing for better inventory control.

- Flexible Menu Planning: Adjust menu offerings seasonally or in response to market trends by having ingredients readily available.

When deciding on the specifications of a walk-in freezer, other considerations come into play, such as energy efficiency and layout. By implementing a design tailored to workflow, the kitchen can facilitate smoother operations, reducing the time staff spend retrieving items. Here’s a simple breakdown of factors to consider:

| Factor | Description |

|---|---|

| Temperature Control | Ensure accurate and adjustable settings for various food types. |

| Access Points | Design for efficient access without disrupting the kitchen flow. |

| Insulation Quality | Invest in high-quality materials to lower energy costs. |

Ultimately, a walk-in freezer is not just a storage solution; it is a cornerstone of effective food preparation and service in an industrial kitchen. For more insights on outfitting a commercial kitchen, consider visiting Food Service Warehouse.

Heavy-duty pots and pans withstand the intensity of an industrial kitchen

In the heart of every bustling industrial kitchen, heavy-duty pots and pans are the unsung heroes, providing culinary professionals with the reliability and durability they need. Crafted from premium materials such as stainless steel, cast iron, and aluminum, these kitchen essentials are designed to withstand extreme heat and prolonged use. Their thick bases ensure even heat distribution, reducing the risk of scorching and enabling chefs to execute delicate sauces, hearty stocks, or perfectly seared proteins with ease. The longevity of these tools makes them a wise investment; a well-maintained heavy-duty pot can last for decades, even under the relentless pressure of daily service.

Moreover, the versatility of these robust cookware pieces allows chefs to seamlessly transition from stovetop to oven, making them ideal for everything from blistering sautéing to slow-roasting. When purchasing, consider options with ergonomic, heat-resistant handles that ensure safety and comfort during use. Features like non-stick coatings or easy-to-clean surfaces can also enhance productivity. Look for esteemed brands known for their quality and performance, such as Woll USA, which provide professional-grade offerings that meet the demanding standards of culinary experts.

Sufficient knives and cutting boards promote safe food prep in an industrial kitchen

In an industrial kitchen, having the right knives and cutting boards is crucial for ensuring efficient and safe food preparation. High-quality knives, ranging from chef’s knives to paring knives, allow chefs to execute precision cuts while minimizing the risk of accidents. It’s essential to have enough knives on hand to handle different tasks, such as chopping vegetables, slicing meat, and filleting fish. Each knife should be specific to its purpose, not only for effectiveness but also to prevent cross-contamination. Proper knife maintenance, including regular sharpening and storage, is vital to maintaining their performance and safety.

Equally important are cutting boards, which serve as the primary work surface for food preparation. A diverse selection of boards can significantly reduce the risk of foodborne illnesses by keeping raw and cooked foods separate. Consider using color-coded boards to easily differentiate between meats, vegetables, and bakery items, allowing chefs to streamline their workflows while adhering to safety protocols. In an industrial kitchen, investing in durable, washable materials for cutting boards is essential for maintaining hygiene and preventing damage over time. Together, a well-stocked array of knives and cutting boards lays the foundation for a safe and efficient cooking environment, enabling culinary professionals to deliver high-quality dishes consistently. For more tips on kitchen safety and equipment, visit foodsafety.gov.

Access to industrial kitchen appliances enhances culinary artistry and efficiency

In the world of culinary arts, a well-equipped kitchen is where creativity flourishes. Having access to industrial-grade kitchen appliances not only broadens the scope for experimenting with new recipes but also enhances the overall quality of the dishes being prepared. These high-performance tools perform tasks quickly and consistently, allowing chefs to focus more on the artistry of cooking rather than the mechanics. By incorporating features such as precise temperature control, rapid cooking times, and multi-functionality, professional-grade appliances elevate the cooking experience. Chefs can explore diverse cooking techniques, from sous vide to flash frying, pushing the boundaries of flavor and presentation.

Efficiency is another critical advantage brought by industrial kitchen appliances that transforms the workflow in busy culinary environments. High-capacity tools such as commercial mixers, blast chillers, and industrial ovens enable multiple dishes to be prepared simultaneously without compromising on quality. This speed not only reduces wait times for customers but also allows chefs to manage larger orders and serve food while it’s at its peak freshness. Additionally, these appliances often come equipped with energy-saving features, providing both sustainability and cost savings for restaurants. With the right tools at their disposal, culinary professionals can maintain high standards of excellence while increasing productivity, ultimately leading to satisfied customers and a thriving business.

A preparation sink is crucial for washing ingredients in an industrial kitchen

A preparation sink is an indispensable fixture in the bustling environment of an industrial kitchen, designed to streamline the washing and prepping of ingredients efficiently. These sinks provide ample space, allowing chefs to clean large quantities of produce and meats before cooking. The use of a dedicated washing area minimizes cross-contamination and promotes better food safety practices, which are paramount in a professional culinary setting. With features like deep basins and high splash guards, preparation sinks are tailored to handle the rigors of daily use.

Moreover, durability and ease of maintenance are key factors that make these sinks essential. Constructed from high-quality stainless steel, they resist wear and tear, ensuring long-lasting performance. This material is not only easy to clean but also helps combat bacteria, keeping the kitchen environment healthy. Integrating a preparation sink into your kitchen layout enhances workflow, allowing chefs to stay efficient and organized. For additional insights on kitchen efficiency, consider visiting Food Service Warehouse for expert advice and equipment recommendations.

Fire safety equipment protects staff and operations in an industrial kitchen

- Fire Extinguishers: Essential for rapid response, these should be readily accessible and strategically placed around the kitchen. Class K extinguishers, designed specifically for grease fires, are particularly crucial in an industrial cooking environment.

- Fire Blankets: Useful for smothering flames on cooking equipment or clothing, fire blankets are an essential addition that provides an alternative means of fire suppression.

- Fire Alarms and Smoke Detectors: These devices should be installed at various locations to provide early detection of smoke or fire, ensuring timely evacuation and response.

- Sprinkler Systems: An automatic sprinkler system can significantly reduce damage from fires by releasing water when heat levels exceed safe thresholds.

| Type of Equipment | Function | Maintenance Frequency |

|---|---|---|

| Fire Extinguishers | Put out small fires | Monthly inspection |

| Fire Blankets | Smother flames | Annual check |

| Smoke Detectors | Detect fire/smoke presence | Biannual testing |

| Sprinkler System | Automatic fire suppression | Annual maintenance |

Ensuring that your staff is trained to use this equipment effectively is equally important. Regular fire drills and safety training sessions will empower your team to act decisively in emergency situations, minimizing risk and damage. Furthermore, establishing clear communication protocols regarding fire emergencies helps maintain an organized response, ensuring that staff know exactly where to go and what to do.

For more detailed information on fire safety protocols specific to culinary environments, you can visit [NFPA](https://www.nfpa.org). Implementing these practices and equipment not only protects personnel but also safeguards the operational integrity of the kitchen, allowing for a focused and safe working environment.

Floor mats minimize slipping hazards in a bustling industrial kitchen environment

In the hectic atmosphere of an industrial kitchen, where both speed and safety are paramount, proper flooring solutions play a crucial role in maintaining a hazard-free workspace. Floor mats are indispensable allies in this environment, providing exceptional slip resistance that minimizes the risk of accidents. Whether chefs are prepping ingredients or servers are darting back and forth, these mats are designed to offer a firm grip and stable footing, significantly reducing the likelihood of falls. Their textured surfaces can channel spills away and absorb shock, contributing to the overall comfort of kitchen staff during long shifts.

Choosing the right type of floor mat can greatly enhance safety and efficiency. They come in various materials, such as rubber and anti-fatigue foam, catering to different needs and areas of the kitchen. Consider the following features when selecting floor mats:

- Water-resistance: Essential for areas prone to spills.

- Durability: Mats must withstand heavy foot traffic and the rigors of kitchen environments.

- Easy to clean: Quick and efficient maintenance is a must.

- Thickness: A thicker mat provides better cushioning and support for kitchen personnel.

Investing in high-quality floor mats is not just about compliance with safety regulations; it also boosts the overall morale of the staff, ensuring they feel secure and comfortable while performing demanding tasks. A properly equipped kitchen will prioritize safety, and managers can find expert guidance on selecting appropriate mats through resources like The American Cleaning Institute.

Stainless steel surfaces ensure hygiene and durability in any industrial kitchen

In the bustling environment of an industrial kitchen, where speed and precision are paramount, having surfaces that can withstand intense usage while ensuring optimal hygiene is crucial. Stainless steel stands out as the material of choice for countertops, shelving, and equipment thanks to its non-porous nature, which resists bacteria and other pathogens. Whether it’s a preparation area or storage shelving, stainless steel facilitates easy cleaning and maintenance. This not only complies with health regulations but also minimizes the risk of cross-contamination, a critical factor in food safety.

Beyond hygiene, stainless steel’s durability contributes significantly to the longevity of kitchen equipment and surfaces. Withstand high temperatures, resist corrosion, and face the demands of heavy usage—these qualities make it an invaluable asset in any commercial kitchen. Its sleek, modern aesthetic also elevates the overall ambiance, presenting a professional appearance that clients and diners appreciate. For those looking to delve deeper into the benefits of stainless steel in kitchen design, resources can be found at healthline.com. Whether outfitting a new establishment or upgrading an existing space, investing in stainless steel surfaces pays off through enhanced efficiency and safety.

Food storage containers help keep supplies fresh in an organized industrial kitchen

In the bustling environment of an industrial kitchen, maintaining the freshness of ingredients is crucial for both quality and safety. Food storage containers come in a variety of styles and materials, allowing chefs to choose options that best suit their needs while ensuring that supplies stay organized. Airtight containers, for example, can help eliminate moisture and air exposure, significantly prolonging the shelf life of spices, grains, and other perishable products. Color-coded containers can also facilitate quick identification and access, streamlining the cooking process during peak service hours.

Moreover, investing in stackable and transparent storage options maximizes space efficiency, making it easier to manage inventory and reduce waste. By implementing a labeling system on these containers, kitchen staff can quickly track expiration dates and avoid the risk of using spoiled ingredients. Utilizing quality storage solutions leads to an organized setup that not only boosts productivity but also enhances the culinary experience. For tips on selecting the right containers for your kitchen, check out WebstaurantStore.

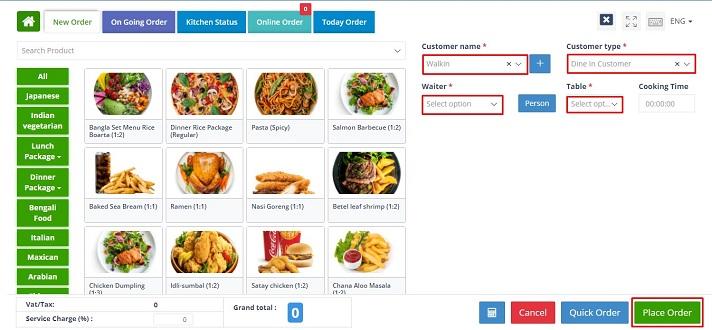

A reliable point-of-sale system simplifies order management in an industrial kitchen

In the fast-paced environment of an industrial kitchen, a dependable point-of-sale system is indispensable for streamlining order management. This technology not only facilitates the efficient tracking of customer orders but also enhances communication between different kitchen stations. By integrating order management with inventory tracking, chefs and staff can easily maintain an accurate flow of ingredients and supplies, ensuring that everything runs smoothly without the risk of over-ordering or running out of essential items.

A well-implemented point-of-sale system can also provide valuable insights into customer preferences and order patterns, enabling chefs to tailor their menus and improve customer satisfaction. Features such as real-time reporting, mobile accessibility, and customizable order types empower kitchen staff to adapt to varying workloads seamlessly. The integration of these systems can reduce errors, minimize prep times, and enhance overall service speed. By utilizing a modern POS solution, industrial kitchens can ensure they remain competitive in a crowded marketplace, while also delivering a consistently high-quality dining experience. For further insights on choosing the right system, you can visit Tailored POS.

First-aid kits are essential for safety in a high-paced industrial kitchen setting

In the bustling environment of an industrial kitchen, accidents can happen in the blink of an eye. Having a well-stocked first-aid kit readily available can make all the difference between a minor mishap and a serious injury. Ensure that your team members are not only aware of its location but also trained on how to utilize the supplies within it effectively. A comprehensive first-aid kit should include a variety of items to address common kitchen injuries such as cuts, burns, and allergic reactions. The integration of proper safety practices helps in creating a culture that prioritizes employee well-being and reduces downtime.

When assembling your first-aid supplies, consider including these essential items:

- Adhesive bandages – for minor cuts and scrapes

- Gauze and adhesive tape – crucial for larger wounds

- Antiseptic wipes – to clean wounds before bandaging

- Burn cream – invaluable for treating food or equipment burns

- Disposable gloves – to maintain hygiene during treatment

- Surgical scissors – for cutting tape or clothing away from wounds

- Cold packs – to reduce swelling and relieve pain

| Item | Purpose |

|---|---|

| Bandages | Cover and protect minor cuts |

| Antiseptic | Prevent infections in open wounds |

| Burn Gel | Soothing treatment for burns |

| Emergency Blanket | Retain body heat in case of shock |

For further guidance on how to set up and maintain a first-aid kit tailored for industrial kitchens, check out resources from the American Red Cross. Remember, preparedness is the key to minimizing risks and ensuring a safe working environment for all kitchen staff.

Label maker systems facilitate inventory management in any industrial kitchen

In a bustling industrial kitchen, efficiency is key, and label maker systems emerge as indispensable allies in maintaining organized inventory management. By providing a clear and concise way to label ingredients, equipment, and storage locations, these systems help ensure that everything has its place. With the ability to generate consistent labels quickly, staff can easily locate and track supplies, allowing for a smoother workflow and reduced time wasted on searching for items. This streamlined approach also minimizes the risk of cross-contamination by clearly marking allergens or specific dietary ingredients, enhancing food safety protocols.

Moreover, utilizing a label maker system supports real-time inventory tracking, making it easier for kitchen managers to maintain optimal stock levels. By applying labels that include essential information—such as expiry dates, storage instructions, and quantities—staff can immediately recognize what needs to be replenished. The durability of these labels means they withstand the rigors of a kitchen environment, remaining legible even in high-traffic areas. Not only does this contribute to a more efficient workplace, but it also supports sustainability efforts by reducing waste through timely usage of ingredients. For more on effective inventory management tools, check out Inventory Source.

Quality staff training ensures safety and efficiency in an industrial kitchen environment

In an industrial kitchen, the foundation of safety and efficiency lies in diligent staff training. Well-trained employees not only increase productivity but also foster a culture of safety that minimizes risks and accidents. Essential training programs should encompass various areas, such as equipment usage, food safety standards, and emergency procedures. By equipping staff with the necessary skills and knowledge, kitchens can significantly reduce the likelihood of injuries and ensure that food handling meets regulatory standards.

Moreover, ongoing training should not be a one-time event. Regular refresher courses and updates on best practices can help maintain high standards and adapt to evolving industry regulations. Incorporating simulated scenarios, such as handling a kitchen fire or dealing with cuts and burns, prepares staff for real-life situations. Additionally, mentorship programs and peer reviews provide valuable feedback that fosters a cooperative environment. By investing in continuous education, an industrial kitchen can enhance operational efficiency, uphold safety protocols, and create a well-functioning team that thrives under pressure. For more information on effective training strategies, consider visiting foodsafety.gov.

Insights and Conclusions

As we wrap up our exploration of the 24 essential elements every industrial kitchen must have, it’s clear that the backbone of any successful culinary operation lies in the careful selection and integration of the right tools, equipment, and design. From state-of-the-art appliances that boost efficiency to smart storage solutions that keep everything organized, each element plays a crucial role in creating a harmonious workspace where creativity can flourish.

Whether you’re designing a new kitchen from scratch or seeking to optimize your existing setup, remembering these essentials will not only enhance functionality but also improve the overall experience for your culinary team. Every pot, every knife, and every inch of countertop space contributes to the symphony of flavors and techniques that emerge from your kitchen.

So, take a moment to assess your own space. Are you equipped with all the right elements to unleash your culinary potential? With these 24 essentials in mind, you’re one step closer to crafting a kitchen that meets the demands of your culinary vision. Here’s to cooking—and thriving—in an industrial kitchen that truly inspires!