In the bustling heart of any culinary institution, an industrial kitchen serves as the command center where creativity meets precision, and dishes come to life. Behind every exceptional meal lies a well-orchestrated environment—one that is equipped with the right tools, layout, and systems to support chefs and staff in their daily endeavors. This listicle will unveil 24 essential features that define a high-performance industrial kitchen, offering insights into how each element contributes to efficiency, safety, and culinary excellence. Whether you’re a seasoned chef, a culinary entrepreneur, or simply a food enthusiast, you will gain valuable knowledge on the key components that can elevate your cooking space to new heights. Get ready to explore innovations, best practices, and must-have elements that will revolutionize the way you think about kitchen design and function!

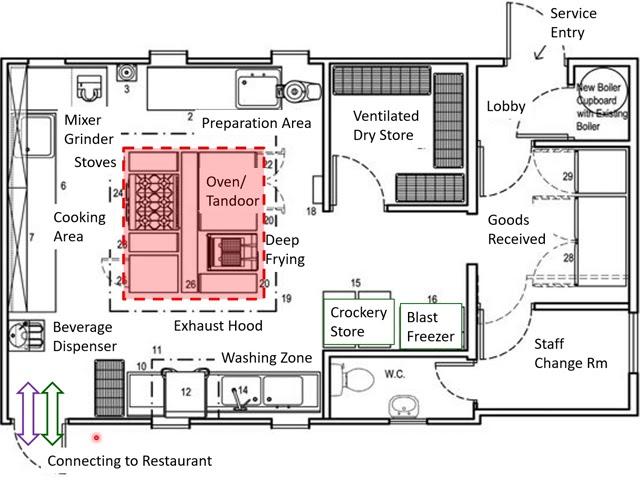

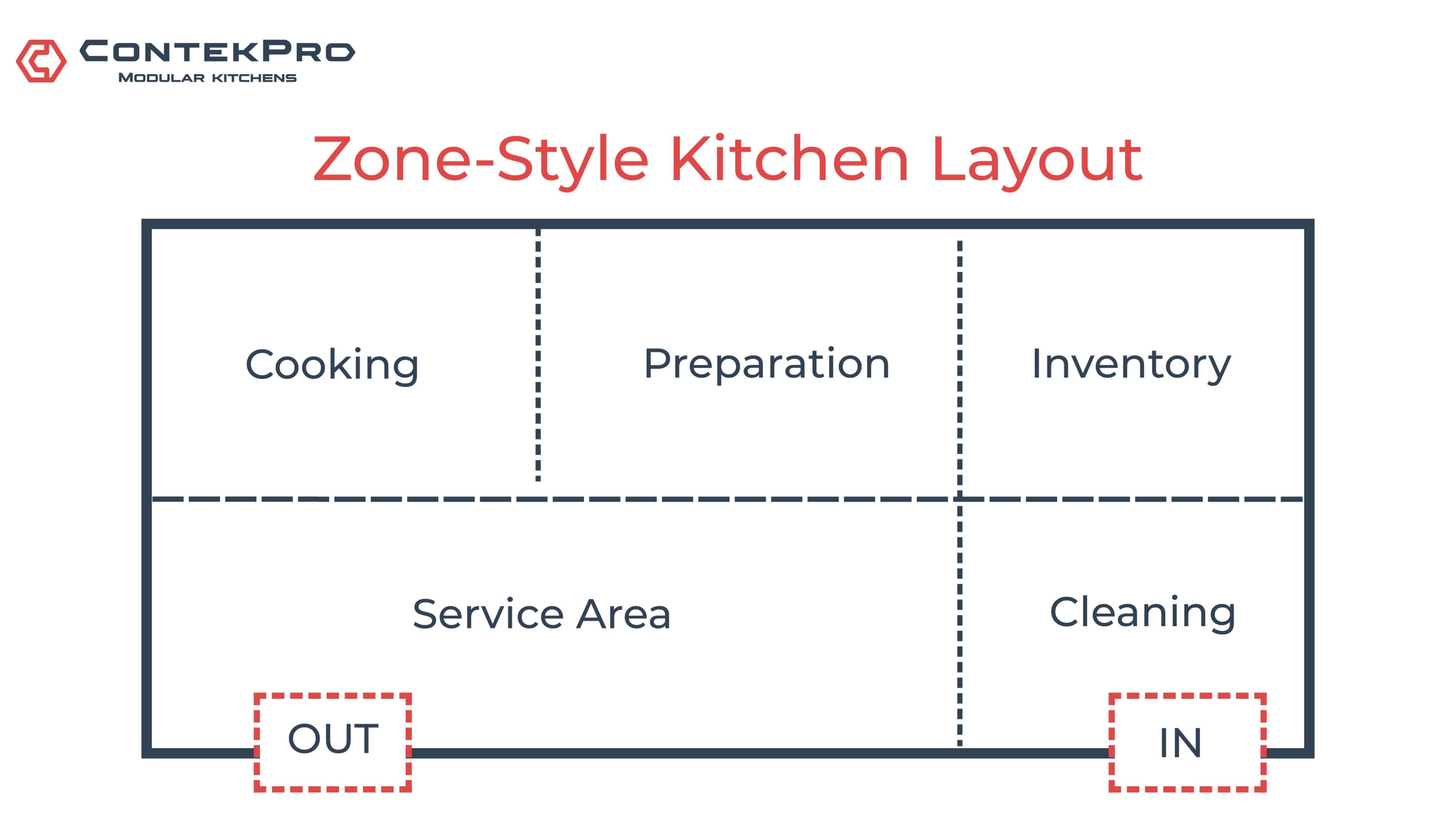

Efficient layout design maximizes workflow in your Industrial Kitchen for optimal productivity

In an industrial kitchen, the layout is not just about aesthetics; it plays a critical role in streamlining processes and ensuring that every team member operates at peak efficiency. By creating specific zones—such as cooking, prep, and plating areas—workers can move fluidly without unnecessary interruptions. A logical flow from the storage room to the preparation area, and finally to the cooking station, minimizes the time and distance staff must travel, facilitating quicker turnaround. Incorporating features like centralized equipment stations, modular workstations, and strategically positioned sinks optimizes each phase of food preparation and cooking.

The importance of a well-planned layout is amplified during busy service hours when time is of the essence. Utilizing tools like open shelving for quick access to supplies and color-coded zones for different food groups can drastically reduce the chance of cross-contamination and enhance productivity. Implementing ergonomic designs not only improves the comfort of kitchen staff but also boosts their efficiency. In addition, keeping a clutter-free environment with designated paths for movement ensures seamless operations. To learn more about maximizing kitchen efficiency, you can visit fsrmagazine.com.

High-quality commercial appliances are essential for consistent performance in an Industrial Kitchen

In an industrial kitchen, the foundation of operational success lies in the selection of high-quality commercial appliances. Utilizing durable and reliable equipment not only enhances the speed and efficiency of food preparation but also ensures a level of consistency in cooking results that is paramount in a professional setting. A variety of appliances, such as heavy-duty ovens, industrial refrigerators, and commercial dishwashers, work in harmony to support the high volume of meal production demanded by restaurants, catering services, and other food establishments. Investing in superior appliances reduces the risk of breakdowns and downtime, ultimately saving money and improving service quality.

Furthermore, premium appliances often come equipped with advanced technology that offers significant advantages over standard models. Features like precise temperature controls, energy efficiency, and user-friendly interfaces streamline workflows and create a safer kitchen environment. Additionally, many high-end commercial appliances are designed with easy maintenance in mind, allowing for quick repairs and minimal operational interruptions. The ability to efficiently manage both peak service periods and everyday operations sets an industrial kitchen apart. For more information on choosing the best commercial kitchen appliances, visit katom.com.

Durable countertops withstand heavy use and maintain hygiene in your Industrial Kitchen

In the fast-paced environment of an industrial kitchen, durability is paramount. Countertops crafted from high-quality materials like stainless steel, quartz, or laminate are specifically engineered to withstand the daily rigors of heavy use. These surfaces not only resist scratches and dents but also hold up against heat, spills, and acidic substances. Furthermore, their smooth finishes allow for easy cleaning and quick wipes, ensuring that any food particles or contaminants are promptly removed. This level of resilience makes them ideal for both prep work and serving areas, maintaining integrity over time even in bustling kitchens.

Another critical aspect of countertops in an industrial setting is hygiene. Non-porous surfaces like quartz and stainless steel prevent bacteria from getting trapped, drastically reducing the risk of cross-contamination. Moreover, these materials can be treated with antimicrobial coatings, enhancing their ability to remain free of harmful pathogens. Consider adding a sturdy unsplash or backsplash made from similar materials to enhance cleanliness and protect walls from spills. Investing in durable, hygienic countertops is not just an operational decision; it is a health-conscious choice that promotes a safer kitchen environment. For more insights on maintaining commercial kitchen hygiene, visit foodsafety.gov.

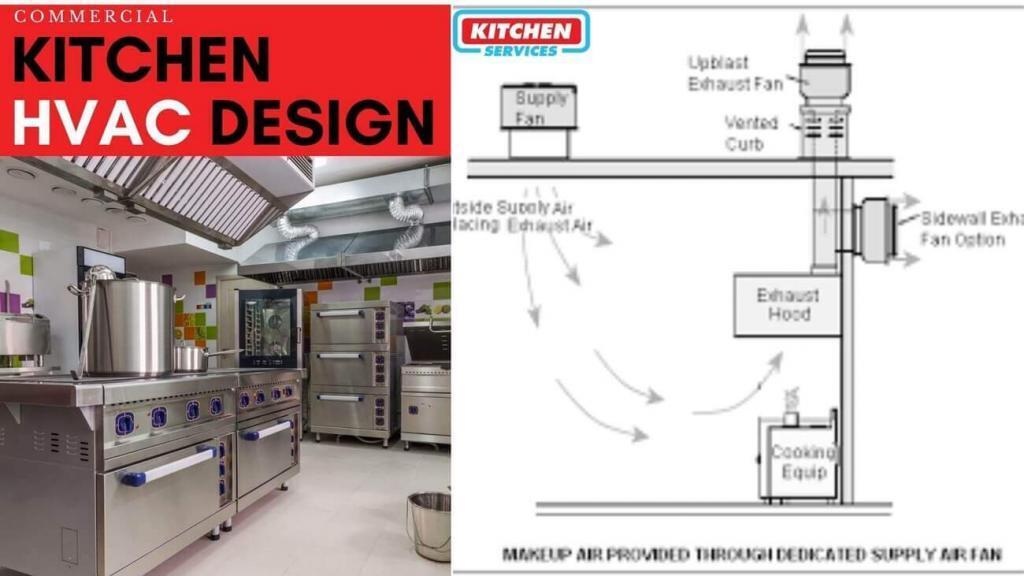

Adequate ventilation systems ensure air quality and temperature control in the Industrial Kitchen

In an industrial kitchen, adequate ventilation systems are crucial for maintaining not only air quality but also ensuring that the temperature remains stable and comfortable for staff. These systems work by removing excess heat, steam, and odors generated during cooking processes. A well-designed ventilation system incorporates features like exhaust hoods, which collect and eliminate airborne contaminants, and make-up air systems that bring in fresh air to balance the environment. This constant circulation not only enhances the cooking experience but also promotes safety by reducing the risk of heat stress among kitchen staff.

Furthermore, air quality is significantly impacted by the presence of filters within the ventilation system. High-performance kitchens often use multi-stage filters to capture grease vapors and airborne particles. The result is a cleaner and healthier kitchen atmosphere. To evaluate the effectiveness of these ventilation systems, it is beneficial to monitor the air quality index (AQI) regularly. Below is a simple table outlining some key metrics related to ventilation performance:

| Metric | Ideal Range | Monitoring Frequency |

|---|---|---|

| Airborne Particulates | 0-35 µg/m³ | Daily |

| CO2 Levels | 400-1000 ppm | Weekly |

| Humidity Levels | 30-50% | Daily |

Ultimately, a robust ventilation system not only elevates the efficiency of kitchen operations but also serves as a cornerstone of a well-functioning industrial kitchen environment. Investing in the right equipment and regularly maintaining it can lead to improved performance and a better culinary experience. For more insights on kitchen ventilation systems, visit hfmmagazine.com.

Ample storage solutions keep the Industrial Kitchen organized and clutter-free for better efficiency

One of the cornerstones of an efficient industrial kitchen is the integration of ample storage solutions that promote organization and eliminate clutter. Wall-mounted shelves are a game-changer, allowing easy access to spices, sauces, and equipment without consuming precious floor space. Modular shelving units can be customized to fit specific needs, adapting to the ever-changing demands of a busy kitchen while maintaining streamlined accessibility. Utilizing clear storage bins enhances visibility, making it simple for staff to find ingredients quickly and reducing food waste. Drawer systems with segmented compartments can keep utensils and tools systematically organized, reducing the time spent searching for what’s needed.

Another effective strategy is implementing designated prep stations equipped with their own storage solutions, such as under-counter cabinets and pull-out racks. This ensures that each cooking area remains tidy and focused, minimizing cross-contamination and promoting workflow efficiency. To further optimize space, consider hanging racks for pots and pans, which not only frees up cupboard space but also adds a touch of style to the kitchen. For bulk ingredient storage, canisters and stackable bins can be employed to maximize vertical space, allowing staff to track stock levels easily. By investing in these storage solutions, kitchens can dramatically improve their operational efficiency, making sure that every square inch is utilized effectively. For more ideas on efficient kitchen organization, check out kitchenconcepts.com.

Smart lighting enhances visibility and creates a comfortable environment in your Industrial Kitchen

Incorporating smart lighting in an industrial kitchen not only improves visibility but also plays a pivotal role in enhancing the overall ambiance. With strategically placed lights, chefs and kitchen staff can navigate the workspace with ease, reducing the risk of accidents during busy hours. LED fixtures that mimic natural daylight can boost concentration and productivity, ensuring that food preparation is both safe and efficient. Moreover, the use of dimmable lighting allows for customizable brightness levels, adapting to the needs of different tasks while reducing glare that could lead to eye strain.

In addition to functionality, smart lighting technology also promotes energy efficiency and sustainability. By utilizing motion sensors and timers, energy consumption can be optimized to ensure that lights are only active when necessary. This not only conserves energy but also extends the lifespan of the lighting fixtures. To further highlight the importance of lighting design, consider creating zones within the kitchen, each with tailored lighting solutions that support varied culinary tasks. For more on effective industrial kitchen designs, visit foodservicewarehouse.com.

Safety features are vital for keeping staff protected in a bustling Industrial Kitchen

In an industrial kitchen where speed and efficiency reign supreme, the safety features of the workspace must never be overlooked. The potential for accidents is amplified by the constant movement of staff and equipment, which is why it is essential to implement robust safety protocols and integrated technology. Features like slip-resistant flooring can significantly reduce the risk of falls, while strategically placed fire extinguishers ensure that staff can respond to emergencies without hesitation. Furthermore, incorporating adequate ventilation systems prevents the buildup of harmful fumes, protecting employees’ respiratory health as they work.

Personal protective equipment (PPE) is equally crucial in safeguarding kitchen staff. Providing heat-resistant gloves, non-slip shoes, and aprons not only protects team members from burns and cuts but also instills confidence in their duties. Moreover, regular training programs on first aid and emergency response ensure that kitchen staff remain vigilant and prepared for any unforeseen incidents. When combined with clearly marked exit routes and an established safety protocol manual, these features create a safer working environment, ultimately enhancing morale and efficiency. For more insights into workplace safety, check out OSHA.gov.

Easy-to-clean surfaces minimize upkeep and promote cleanliness in the Industrial Kitchen

In the bustling environment of an industrial kitchen, where efficiency and cleanliness are paramount, the utility of easy-to-clean surfaces cannot be overstated. Materials such as stainless steel, quartz, and epoxy resin have risen to prominence, offering not just durability but also a seamless, non-porous finish that resists staining and harboring bacteria. This simplified surface design promotes a hassle-free cleaning process, ensuring that chefs can focus more on culinary creation rather than time-consuming maintenance.

Incorporating features such as rounded corners and integrated sinks further enhances the practicality of these surfaces, allowing for smooth transitions and reducing grime build-up. Consider the following benefits of easy-to-clean surfaces in industrial kitchens:

- Quick Wipe Down: Smooth finishes require minimal effort to remove spills and splashes.

- Reduced Bacterial Growth: Non-porous materials prevent the absorption of liquids.

- Longevity: Durable surfaces stand the test of time, lowering replacement costs.

- Enhanced Hygiene Compliance: Easier cleaning helps meet health and safety standards.

| Surface Material | Cleaning Difficulty | Resistant To |

|---|---|---|

| Stainless Steel | Easy | Bacteria, stains |

| Quartz | Moderate | Scratches, heat |

| Epoxy Resin | Very Easy | Chemicals, moisture |

In the quest for a high-performance industrial kitchen, opting for surfaces that facilitate ease of cleaning is not just a preference but a necessity. For further insights into maintaining a pristine kitchen environment, visit FoodSafety.gov.

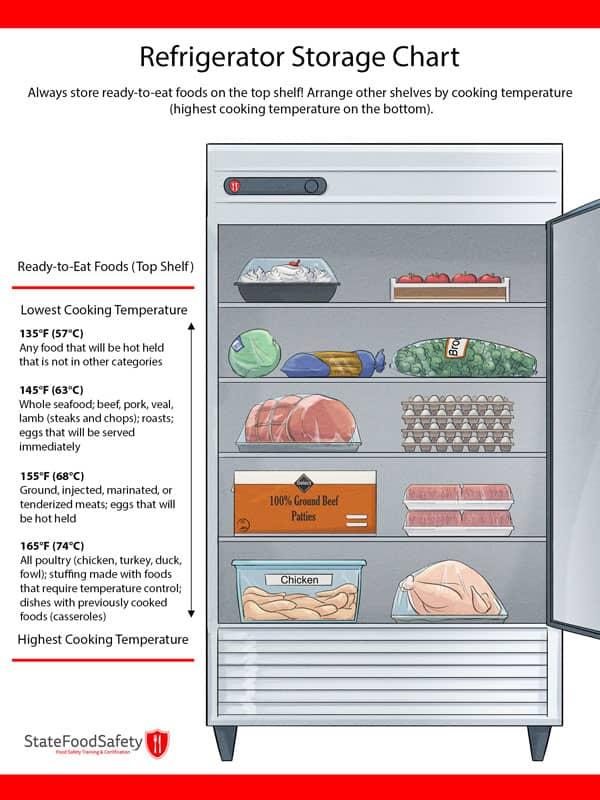

State-of-the-art refrigeration systems keep ingredients fresh in your Industrial Kitchen

In a bustling industrial kitchen, maintaining the integrity and freshness of ingredients is paramount. State-of-the-art refrigeration systems are designed not only to provide optimal cooling but also to enhance the overall efficiency of kitchen operations. These advanced systems often feature a range of technology that ensures temperature consistency and proper airflow, reducing the risk of spoilage. Key innovations include:

- Digital Temperature Controls: Allow precise adjustments based on specific ingredient needs.

- Smart Monitoring: Systems that alert kitchen staff to any temperature fluctuations through mobile notifications.

- Energy Efficiency: Utilizing eco-friendly refrigerants and energy-saving designs to minimize environmental impact.

- Zone Cooling: Separate compartments maintaining different temperatures to cater to various ingredients.

Furthermore, modern refrigeration solutions come equipped with features that enhance hygiene and reduce the risk of contamination. Many units now include anti-bacterial surfaces and easy-to-clean designs that streamline maintenance. In addition, remote diagnostics and management systems empower chefs to monitor their stock in real-time, ensuring nothing goes to waste. The advantages of these cutting-edge systems include:

- Rapid Cooling Technology: Quick cooling capabilities to preserve flavor and texture.

- Self-Defrosting: Eliminates the need for manual defrosting, saving time and labor costs.

- Integrated Shelving: Adjustable shelving units for optimized storage and organization.

- Accessibility Features: Designed for easy access to stock while minimizing cross-contamination risks.

Incorporating high-performance refrigeration into your industrial kitchen not only guarantees ingredient freshness but also enhances productivity and operational efficiency.

For more options on advanced refrigeration technology, visit Hoshizaki.

Energy-efficient equipment reduces costs and environmental impact in an Industrial Kitchen

Investing in energy-efficient equipment is not just a smart financial move for industrial kitchens; it also plays a crucial role in minimizing the overall environmental footprint. High-efficiency ovens, dishwashers, and refrigeration systems are designed to consume less electricity and water, leading to significant reductions in utility bills over time. For instance, energy-efficient gas ranges can lower gas consumption by up to 30%. Additionally, many of these appliances utilize advanced technology that optimizes performance while reducing waste. By incorporating such equipment, kitchens can maintain operational excellence while aligning with sustainability goals.

Moreover, adopting energy-efficient technology can lead to smarter, more streamlined kitchen operations. Implementing energy management systems allows kitchen staff to monitor energy usage in real-time, helping to identify areas for improvement. Features such as programmable thermostats and automated lighting systems further enhance this efficiency. By reducing energy consumption, kitchens not only cut costs but also contribute to a greener environment, thereby fostering a positive public image. For further insights on energy efficiency in commercial kitchens, you can visit energystar.gov.

Workflow zones streamline tasks and improve efficiency in the Industrial Kitchen

In an industrial kitchen, establishing distinct workflow zones is crucial to enhancing productivity and ensuring smooth operations. By creating dedicated areas for specific tasks, kitchen staff can clearly delineate responsibilities and minimize unnecessary movement. Some key zones include:

- Preparation Zone: A space equipped with cutting boards, knives, and mixers, specifically for food prep.

- Cooking Zone: Positioned for stoves, ovens, and fryers, designed for high-temperature tasks.

- Plating Zone: A designated area with aesthetic tools to enhance the visual presentation of dishes before serving.

- Cleaning Zone: Organized with sinks, dishwashers, and drying racks ensuring cleanliness and hygiene.

Each zone contributes to a logical flow of work, allowing staff to transition seamlessly between tasks while maintaining focus and efficiency. For example, placing the Preparation Zone adjacent to the Cooking Zone minimizes the time spent transporting ingredients and tools. Moreover, effective zoning can help reduce the risk of accidents and cross-contamination, as specific areas are dedicated solely to their intended purposes. To understand more about optimizing workflow in industrial kitchens, check out resources on culinary efficiency at ChefSteps.

Well-placed electrical outlets ensure accessibility throughout the Industrial Kitchen

In the bustling environment of an industrial kitchen, the strategic placement of electrical outlets is paramount for enhancing efficiency and safety. Convenience is key, as outlets located near cooking stations and prep areas eliminate the hassle of long, unsightly cords that can be a trip hazard. Ensuring that outlets are installed at accessible heights also aids in a more organized kitchen layout—chefs can plug in numerous appliances like food processors, blenders, and mixers without obstructing pathways or workspaces. A well-thought-out design not only maximizes productivity but also reinforces professionalism in the culinary environment.

To make the most of an industrial kitchen’s electrical capabilities, consider the following outlet planning strategies:

- Position outlets at least every 4-6 feet on countertops to facilitate diverse equipment accessibility.

- Install GFCI (Ground Fault Circuit Interrupter) outlets near sinks and water sources for safety.

- Incorporate multi-outlet strips or workstation panels for flexibility in equipment use.

- Ensure the inclusion of specialized outlets for high-wattage appliances, ensuring they can operate safely without overloading circuits.

Additionally, the integration of hidden outlets in cabinetry can keep surfaces clean and free from clutter while granting quick access when needed. By prioritizing outlet placement, industrial kitchens can maintain a workflow that not only meets the demanding pace of busy culinary services but also upholds safety standards.

| Outlet Type | Location | Purpose |

|---|---|---|

| Standard Outlets | Countertops | General equipment use |

| GFCI Outlets | Near Sinks | Water safety management |

| High-Wattage Outlets | Back Wall | For heavy-duty appliances |

| Multi-Outlet Strips | Workstations | Flexibility in appliance use |

For more insights on kitchen design and functionality, revisit Kitchens.com for additional tips and guidelines.

Reliable plumbing systems are crucial for a fully functional Industrial Kitchen

In the bustling environment of an industrial kitchen, every element needs to work together seamlessly, particularly the plumbing systems. Reliable plumbing infrastructure ensures that water supply and drainage operate efficiently, minimizing the risk of leaks or blockages that could disrupt operations. Without a well-designed and maintained plumbing system, food preparation and cleaning tasks could face significant delays, potentially leading to decreased productivity and higher operational costs. To guarantee a consistently smooth workflow, consider implementing features such as:

- High-capacity drains to handle large volumes of water.

- Backflow prevention devices to protect against contamination.

- Regular maintenance schedules to preemptively address plumbing issues.

- Automatic shut-off valves for emergency situations.

A well-planned plumbing layout also promotes hygiene and safety, which are paramount in food service environments. The installation of splash-proof and corrosion-resistant materials, along with the strategic placement of sinks and handwashing stations, fosters a clean and efficient workspace. Additionally, integrating a robust wastewater management system can significantly reduce risks associated with drainage backups. Key considerations include:

- Grease traps to prevent blockages in sewer lines.

- Insulated piping to reduce energy loss and prevent freezing.

- Water softening systems to enhance equipment lifespan.

Investing in these essential plumbing components is a vital step towards ensuring a high-performance industrial kitchen. Learn more about commercial kitchen requirements at FoodSafety.com.

Ergonomic designs minimize strain and enhance comfort in the Industrial Kitchen

In an industrial kitchen, where the pace can be relentless and the workload demanding, ergonomic designs play a crucial role in reducing physical strain on chefs and kitchen staff. With features thoughtfully integrated into workstations and appliances, these designs prioritize the natural movements of the body, thus minimizing fatigue and preventing injuries. Elements such as adjustable-height workstations, which accommodate different user preferences, and anti-fatigue mats that provide cushioning for standing positions can make a significant difference in daily operations. Moreover, strategically placed tools and equipment help reduce excessive bending or reaching, fostering a more efficient workflow.

Key ergonomic features go beyond just comfort; they also enhance overall productivity while promoting a healthier workplace. Consider the incorporation of lightweight utensils that reduce strain during extended usage, or the use of sliding shelves that minimize the effort needed to access frequently used items. Furthermore, many modern kitchens are adopting curved counter designs that support fluid movement while prepping meals. These thoughtful choices not only enhance comfort but also help maintain a high standard of culinary excellence. For more insights on ergonomic designs in professional kitchens, visit ergonomics.org.

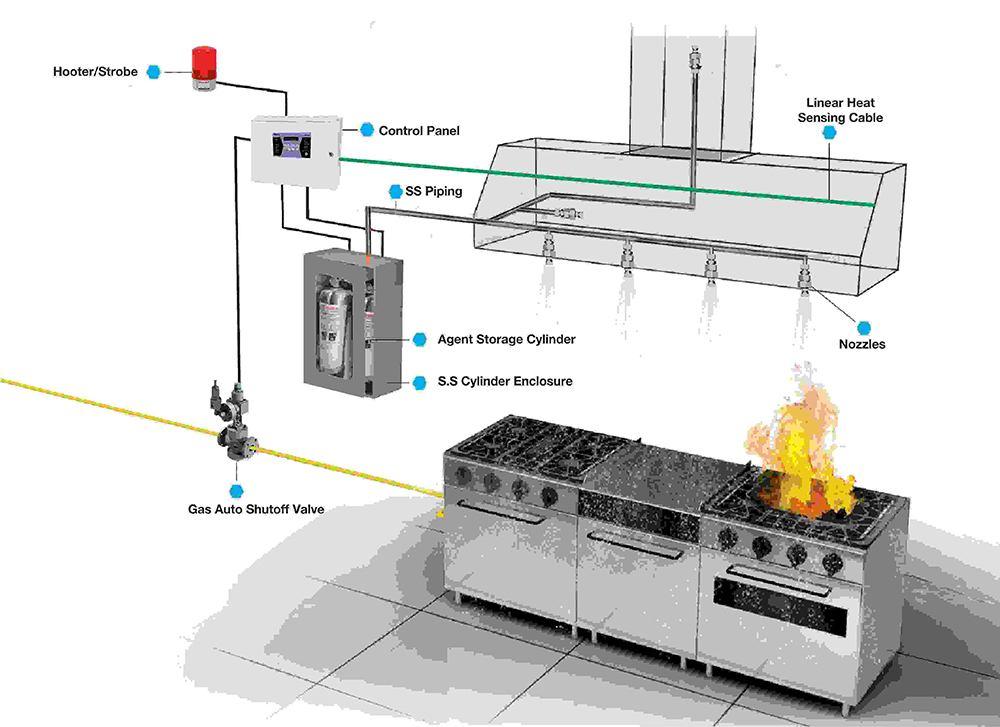

Fire safety measures are essential for preventing hazards in the Industrial Kitchen

- Automatic Fire Suppression Systems: Installation of automatic fire suppression systems is critical. These systems can detect and extinguish fires quickly, reducing the risk of extensive damage. They are especially vital in areas where high heat and open flames are common.

- Regular Maintenance Checks: Scheduling routine inspections and maintenance of fire safety equipment ensures that everything is in working order. This includes fire extinguishers, alarms, and sprinkler systems, contributing to a safer work environment.

- Clear Evacuation Routes: Clearly marked and unobstructed evacuation routes are necessary for safe exits in the event of a fire. All staff must be trained to know these routes to ensure quick and safe evacuation.

- Employee Training Programs: Conducting regular fire safety training sessions for all kitchen staff is essential. This training should cover emergency procedures, the proper use of fire extinguishers, and how to respond in various fire scenarios.

- Proper Storage of Flammable Materials: Ensuring that flammable materials are stored in approved containers and away from heat sources minimizes risk. This practice helps to prevent accidental ignition and maintain a safer environment.

| Fire Safety Measure | Importance |

|---|---|

| Fire Extinguishers | First line of defense against small fires |

| Smoke Alarms | Early detection of smoke for timely intervention |

| Heat Sensors | Alert staff to dangerous temperature rises |

| Fire Drills | Practice and awareness enhance readiness |

| Emergency Contacts | Quick access to fire department and emergency services |

Employing these measures not only safeguards resources but also enhances the overall efficiency of the industrial kitchen. Regularly updating the staff on fire safety protocols and ensuring compliance with regulations can greatly reduce hazards. For more comprehensive fire safety tips, visit nfpa.org.

Modular shelving systems provide flexibility for growing stock in your Industrial Kitchen

In the fast-paced environment of an industrial kitchen, adaptability is paramount, especially when it comes to storage solutions. Modular shelving systems are an excellent choice for kitchens that need to respond quickly to changing inventory and demands. With the ability to customize configurations, these shelving units allow chefs and kitchen staff to maximize vertical space while keeping ingredients, utensils, and equipment organized and easily accessible. Their interchangeable components mean that you can rearrange or expand your shelving as your stock grows, making it easy to accommodate seasonal changes in menu offerings or fluctuations in supply.

Moreover, modular shelving enhances workflow efficiency by allowing easy segregation of items. Consider the following benefits:

- Space Optimization: Adjustable heights and depths can be tailored to fit specific items.

- Easy Accessibility: Stock is organized in a manner that minimizes search time.

- Durability: Constructed from robust materials designed withstand daily wear and tear.

- Hygienic Designs: Many models feature antimicrobial coatings for easier cleaning.

Additionally, investing in high-quality modular shelving not only improves the layout of your kitchen but also adds an aesthetic appeal to the workspace. With sleek designs, these systems can elevate the overall atmosphere, making it not just a functional area but also a visually pleasing environment for culinary creativity. For more insights into optimizing your kitchen space, consider visiting kitchensolutions.com.

Employee training on equipment ensures safe and effective operation in the Industrial Kitchen

In the fast-paced environment of an industrial kitchen, proper training on equipment usage is critical to maintaining both safety and efficiency. Comprehensive employee training programs help ensure that all staff members understand the functionality and safety features of complex kitchen machinery, from ovens and stoves to mixers and slicers. This knowledge aids in preventing accidents, reducing repair costs, and minimizing downtime, allowing for a smoother workflow during peak hours. Staff familiar with their tools are more likely to utilize them correctly, ultimately enhancing overall culinary output and service quality.

Moreover, regular training refreshers are equally important in an industry where new technologies and equipment are frequently introduced. Creating an in-house training protocol or partnering with equipment suppliers can equip your team with the necessary skills to adapt to innovations and maintain high standards. Comprehensive training includes not only operational techniques but also encompasses safety protocols, hygiene practices, and emergency procedures. By investing in your employees’ knowledge of equipment, you lay the groundwork for a more competent and confident workforce.

Additionally, these training programs can incorporate elements such as:

- Hands-on practice to reinforce learning;

- Visual aids for quick reference;

- Regular assessments to evaluate skills;

- Feedback sessions to improve training techniques;

- Cross-training to diversify employee skill sets.

Investing in a robust training framework not only enriches your staff’s capabilities but also solidifies your kitchen’s reputation for consistently delivering excellence. By ensuring safe and effective operation, you fortify the foundation for culinary creativity and operational success. For additional insights on effective training programs, you can visit Food Service Warehouse.

Integrated technology helps track inventory and manage orders in the Industrial Kitchen

In a bustling industrial kitchen, integrated technology serves as the backbone of efficient operations, allowing for seamless tracking of inventory and order management. This technology harnesses advanced software and RFID systems to maintain real-time visibility over stock levels, ensuring that ingredients are always fresh and available. Automated alerts notify staff when supplies are dwindling, minimizing waste and allowing for proactive replenishment. Moreover, these systems can streamline the ordering process by synchronizing with suppliers, enabling easy online orders directly from the kitchen’s inventory system.

Additionally, the combination of cloud-based platforms and mobile apps facilitates smooth communication among kitchen staff, managers, and suppliers. Order management becomes a breeze with features like:

- Customizable order templates for quick reordering

- Sales forecasting via data analytics to prevent shortages

- Integrated delivery tracking to monitor incoming supplies

- Inventory audits that can be conducted digitally and in real-time

- User-friendly dashboards to visualize stock levels and sales trends

These innovations ensure that every dish is crafted with precision, reducing errors and elevating overall kitchen productivity. For more on leveraging technology in food service, visit Food Management.

Sustainable practices promote eco-friendliness in your Industrial Kitchen operations

- Energy-efficient appliances: Upgrading to energy-efficient ovens, refrigerators, and dishwashers can significantly reduce energy consumption. Look for appliances with Energy Star certification to ensure you are making a sustainable choice.

- Water conservation measures: Implement low-flow faucets and dishwashing systems to minimize water waste. Regular maintenance of plumbing can also prevent leaks and excess water usage.

- Waste reduction strategies: Incorporate composting and recycling programs to manage kitchen waste effectively. Partner with local farms to donate excess food, preventing it from going to landfills.

- Sustainable sourcing: Prioritize suppliers who follow ethical farming practices. Choosing organic, local, and seasonal ingredients not only supports your community but also reduces carbon emissions associated with transportation.

- Eco-friendly packaging: Utilize biodegradable or compostable packaging for takeout and delivery. This helps minimize plastic waste and showcases your commitment to sustainability.

| Practice | Benefit |

|---|---|

| Energy-efficient appliances | Lower electricity bills and decreased carbon footprint |

| Water conservation measures | Cost savings and reduced water waste |

| Waste reduction strategies | Minimized landfill contribution and potential tax benefits |

| Sustainable sourcing | Fresh ingredients and support for local economies |

| Eco-friendly packaging | Enhanced brand image and reduced plastic pollution |

Implementing these sustainable practices not only contributes to a healthier planet but also enhances the efficiency and image of your industrial kitchen. For a deeper understanding of sustainable practices in the culinary world, check out [Sustainable Restaurant Association](https://sra.org.uk).

Employee areas create a comfortable break space within the Industrial Kitchen environment

In an industrial kitchen, the hustle and bustle can take a toll on employees, making it vital to integrate areas specifically designed for relaxation and rejuvenation. A well-thought-out break space not only fosters a positive environment but also enhances productivity when employees return to their tasks. These employee areas can encompass various elements that make a significant difference in the overall kitchen experience, ensuring that staff feel valued and comfortable. Consider including features such as comfortable seating, natural lighting, and calming color schemes to facilitate relaxation during breaks.

Moreover, incorporating amenities that cater to the needs of kitchen staff can elevate the break space experience. Providing lockers for personal belongings, easily accessible refreshment stations, and even mini-gardens can promote a sense of well-being and community. These elements encourage employees to step away from their duties and recharge effectively. A well-designed break area may also serve as a social hub where employees can connect, share experiences, and foster teamwork, ultimately contributing to a more harmonious workplace. Explore more about enhancing employee well-being at wellness.gov.

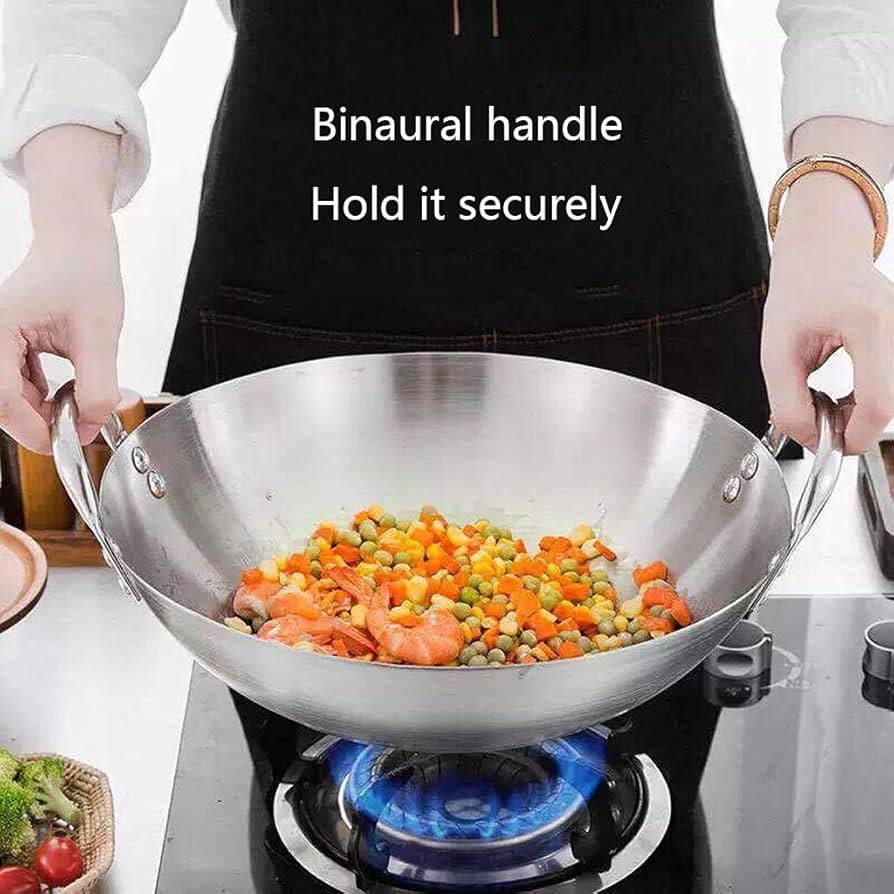

Quality cookware withstands the rigors of high-volume cooking in the Industrial Kitchen

In an industrial kitchen where efficiency and excellence reign supreme, quality cookware is non-negotiable. High-performance pots, pans, and baking sheets are designed to endure the relentless demands of high-volume cooking. Crafted from durable materials like stainless steel, cast iron, and heavy-gauge aluminum, these tools are capable of withstanding extreme temperatures without warping or degrading. Additionally, the ability to distribute heat evenly ensures that meals are cooked perfectly every time, which ultimately enhances the overall quality of the dishes prepared.

Moreover, professional-grade cookware often features reinforced edges that resist chipping and scratching, along with non-stick coatings that facilitate easy release and clean-up. For large-scale operations, the availability of variety in sizes and forms is essential, enabling chefs to tackle everything from sauces to boiling stocks efficiently. Let’s not forget ease of handling; many industrial cookware pieces come equipped with ergonomic handles designed to stay cool, providing safety and comfort even during the busiest service hours. Exploring options from trustworthy suppliers such as KaTom can offer insights into the best materials and designs for your kitchen’s specific needs.

Regular maintenance schedules keep equipment performing efficiently in the Industrial Kitchen

Implementing regular maintenance schedules for equipment in an industrial kitchen is crucial for ensuring peak performance and longevity. By adhering to a routine maintenance plan, kitchen operators can minimize the risk of unexpected breakdowns and costly repairs. This proactive approach allows staff to identify and address minor issues before they escalate into significant problems, which can disrupt kitchen operations. Essential aspects of such a plan include:

- Cleaning: Regularly clean equipment to prevent buildup that could cause malfunction or health hazards.

- Calibration: Ensure that all settings are correct and up to date for accurate operation, especially for cooking and refrigeration equipment.

- Inspections: Conduct periodic checks to ensure all machinery is functioning correctly and safely.

- Lubrication: Keep moving parts well-lubricated to reduce friction and wear.

To further streamline this process, creating a maintenance log is advisable. This log can track service dates, issues encountered, and parts replaced, effectively serving as both a memory aid and a historical reference. Establishing a clear schedule helps maintain consistency, allowing kitchen staff to plan around maintenance activities. The typical breakdown of maintenance tasks can be organized as follows:

| Equipment | Maintenance Frequency | Responsibility |

|---|---|---|

| Ovens | Monthly | Chef |

| Refrigerators | Weekly | Kitchen Staff |

| Dishwashers | Bi-Weekly | Maintenance Team |

Incorporating a diligent maintenance strategy not only enhances equipment efficiency but also ensures a safer and more productive kitchen environment. For more insights on maintaining industrial kitchen equipment, consider visiting FSIS.

Established menu planning optimizes ingredient usage for your Industrial Kitchen

In an industrial kitchen, establishing a well-structured menu planning process is key to leveraging ingredients efficiently and minimizing waste. By implementing a systematic approach, kitchens can align their inventory management with meal preparation schedules, which helps to ensure that every item on the menu is utilized to its fullest potential. A structured menu takes into account the availability of seasonal produce, ensuring that meals are not only fresh but also cost-effective. Additionally, it allows for the integration of ingredients across multiple recipes, further reducing excess and spoilage.

Moreover, optimizing ingredient usage through menu planning involves careful categorization of dishes based on their cooking methods and ingredient compatibility. This not only enhances workflow efficiency but also promotes creativity in the kitchen. For example, a flexible menu can include a section for weekly specials that highlight underutilized ingredients, making them the star of the show. Some benefits of this practice include:

- Cost Savings: Reduces purchasing of unnecessary items.

- Sustainability: Less food waste contributes to eco-friendly practices.

- Increased Variety: Encourages creative use of ingredients for diverse menus.

To visualize the impact of smart ingredient planning, consider the following table that outlines how one ingredient can be used across multiple dishes:

| Ingredient | Dish 1 | Dish 2 | Dish 3 |

|---|---|---|---|

| Quinoa | Quinoa Salad | Stuffed Peppers | Quinoa Risotto |

| Chicken | Grilled Chicken | Chicken Curry | Chicken Stir-Fry |

| Broccoli | Broccoli Soup | Steamed Broccoli | Broccoli Cheese Casserole |

By embracing the principles of effective menu planning, industrial kitchens can not only streamline their operations but also contribute positively to sustainability efforts. For more insights on optimizing kitchen processes, visit foodservice.com.

Open communication fosters teamwork and efficiency among staff in the Industrial Kitchen

In an industrial kitchen setting, open communication acts as the backbone of cohesive teamwork. When chefs, kitchen staff, and management engage in transparent discussions, it leads to a more synchronized workflow. Daily briefings or huddles can set the tone for efficiency, ensuring that everyone is on the same page regarding menu changes, food safety protocols, and special events. This level of engagement also fosters a culture of feedback, where employees feel empowered to voice their ideas and concerns, ultimately enhancing the creative process in meal preparation and presentation.

Moreover, using collaborative tools and technologies for communication can significantly amplify teamwork. Digital platforms allow for real-time updates and notifications, minimizing the chances of miscommunication that can lead to costly mistakes. Consider implementing shift schedules and task assignments through apps, enabling everyone to understand their responsibilities at a glance. By ensuring that information flows freely, industrial kitchens not only boost morale but also achieve higher levels of productivity. The result is a more dynamic kitchen environment where everyone contributes to success. For more insights on improving kitchen communication, check out culinaryschool.com.

To Wrap It Up

Conclusion: Crafting Culinary Excellence

As we’ve explored in this listicle, the intricacies of a high-performance industrial kitchen extend far beyond mere aesthetics. Each feature, from layout to equipment, plays a critical role in fostering an environment where creativity thrives and efficiency reigns supreme. Whether you’re designing a brand-new space or optimizing an existing one, the principles discussed here serve as a foundational roadmap to elevate your culinary operations.

Embracing these 24 essential features not only enhances productivity and safety but also paves the way for culinary innovation and success. So, as you set out to create an industrial kitchen that meets the demands of today’s dynamic food industry, remember that every detail counts. By investing in a well-designed kitchen, you’re not just building a workspace – you’re crafting an ecosystem where flavors come to life and culinary dreams can be realized. Here’s to high-performance kitchens that inspire chefs and delight tastes!